MAG-VAC TUNNEL TRANSPORTATION (MVTT)

(Development Ongoing)

Table of Contents

———————-—————————

Continuous Flow and Individual Vehicles

BUILDING AND MAINTAINING THE VACUUM

Building and Maintaining the ‘Vacuum

Continuous Flow Exit and Entry

DISASTER PREVENTION and RECOVERY

Combating Cyber-Terrorism—Software Integrity

If the Worst Happens—DISASTER RECOVERY

MVTT features which apply to disaster recovery

OPTIMIZE A MULTIPLICITY OF ADVANTAGES

Design to Support Existing Vehicles

Continuous Flow Dynamic

Maximize Key Competitive Advantages

Deprive Obstructionists of Issues

Reducing Cost

Encourage Participation of Existing Enterprise

Freight First

Solve Problems Before Major Investment

Solve Worst-Case Problems First

This Isn’t Optional

And the Clock is Ticking

—————————————————————————————————

INTRODUCTION

In America The Green New Deal promotes the belief that somehow it’s government that can solve our environmental problems despite the reality that government is restrained by its obligations to the existing socioeconomic reality that forms the foundations of its very existence (elements of which are major polluters)—and is therefore arguably the entity least likely to support the necessary level of transcendent change.

Our Kaimókara Project in the Darien Rainforest, on the other hand, doesn’t look to government at all, but instead aims for Green New Deal-like objectives, as well as exceptional economic vitality and healthy society, through creative solutions involving both dramatic profit-motive and inclusive implementation, and we believe that it will succeed in the relatively simple socioeconomic reality of the Darien.

It involves three critical prerequisites to success—

The understanding that, not within government, but in individual transcendent creativity lies the most powerful key to both economic vitality and a healthy environmental future.

In order to be effective at a level commensurate with the problem, conservation cannot be an afterthought to entrepreneurial solution, but must be implicit in its core and preferably critical to its success.

Our environmental solutions must aim for a motivational mentality powerful enough (think goldrush) to overcome the inevitable resistance of the status-quo—and broad enough to generate positive environmental results commensurate with the enormity of our problem.

How might these three foundational principles fuel conservation efforts in a more complicated America?

Rather than attempt to legislate our fuel-guzzling transportation systems out of existence, for example, how might a transcendent plan look beyond conventional transportation solutions to technological possibilities for which dramatic environmental conservation is an implicit consequence of its operation—rather than a damper on it?

I have in mind a massive, inspirational, and collaborative project or Vacuum Tunnel Transportation, the concept for which was first proposed by Robert Goddard in 1904 and for which a model was first built in 1909 in Russia by Boris Weinberg. During the 1970s, Rand Corporation's Robert Salter Jr. proposed a vactrain connecting cities along the eastern seaboard, and calculated that its only speed limitation would be the curvature of the earth (which, at 15,000 mph would create weightlessness which might sicken the passengers). More recently Mr. Daryl Oster (CEO of ET3 Corp.) had been working on the project and obtained some patents on the concept.

Throughout these years, the principal attraction of the project was speed (with a practical limit at the time considered to be about 3000 mph), but today its major benefit may be that, if properly designed, the project can reduce related energy costs and greenhouse gas emissions by better than 90%—and thus overall transportation related emissions by somewhere around 50%.

A similar idea popped into my head independently in the late 1970s while I was in the midst of building paradigm-shifting software solutions for clients in big business and government. The principal difference between my solution, which I called Mag-Vac Tube Transportation (MVTT), and others which were based on stop-and-go rail structures, was that it was based on a cellular, continuous-flow dynamic, which would integrate existing ground transportation. In 1980 I acquired 150 acres on the coast of Maine which would provide the space to build a physical model of my transportation dynamic, but which also proved to be a great vacation spot for friends and family, Unfortunately, though I continued to design that model in my head, other more urgent projects prevented the realization of this physical model for many years..

Nevertheless, as technology moved forward, new possibilities were incorporated into my design—carbon fiber carrier containers (bullets), an internal vacuum created and sustained by the very motion of the bullets within the structure, solar panel energy sources, better computers, on-board computers, super-conductors etc., etc., until with the arrival of the 21st century it became apparent, not only that emerging technologies made the project more exciting and more viable, but that its potential importance extended far beyond its physical excellence for transportation and energy conservation to national survival and greater global unity.

By 2007 I’d became so enthusiastic that I began the design work necessary for the model on my land on the coast of Maine—which was sadly interrupted by the consequences of the financial crisis.

In 2012 Elon Musk joined the fray when he proposed development of a Hyperloop system in the United States and began hosting an annual competition and encouraging US industry to take up the challenge. Unfortunately, our country's by now infamous dysfunctionality, and inability to challenge the status quo in any meaningful way, seems to be undermining the risk-to-benefit ratio of this project in ways which threaten to doom it in America even as it flourishes in Dubai, where the Hyperloop project even now nears completion of its first instance.

I am talking here about the same widespread dysfunctionality and damaged national ethos which have increasingly undermined the American dream these past 70 years. I am talking about our diminished capacity to think big about the future of our country and a shrinking collective courage which now mirrors more the caution of bankers and hedge-fund managers than the exuberance of creative minds. I am talking about all the missed opportunities to maintain an abundance of the kinds interesting and inspiring middle-class jobs that generated the widespread pride in our country that had long been a keystone of national unity. I am talking about our society’s countless failures to act wisely and in the long-term national interest that have contributed greatly to current negative feelings regarding the political class and the direction of our country—and which led to the broad polarization and dissatisfaction which so lately gave legs to the attack on our capital.

And I am suggesting that, if we fail to address these long-percolating root problems in America now, while the problems and their consequences are so clearly etched out for all to see, we can expect nothing less than the complete demise of the American dream upon which our country was founded.

The resistance inside America to this particular project at this nascent stage is relatively subtle and oblique, but as its true implications become obvious, it will gradually become opposed by the combined efforts of the industries it threatens—all the energy producers—all auto manufacturers—all airlines and airplane manufacturers—highway construction—all rail and mass transportation systems—and all subsidiary manufactures and political entities supporting these industries.

Serendipitously, however, the very clarity of our present predicament presents us with a unique opportunity to focus our attention on this transportation problem and solve it—and thereby blast open the door to other inspirational projects and a prosperous and healthy future. And the fact that the USA has no High-Speed rail at all may actually be an advantage since we would be able to leap directly over high-speed rail to magnetic cannon transportation in a way which could dominate transportation for decades to come.

So how might we proceed?

Such a dramatic departure from traditional transportation systems demands the kinds of equally dramatic benefits which are not apparent in existing Hyperloop efforts. Success demands that we clearly transcend current transportation capabilities and maximize benefits to a degree that will make our project socially and economically irresistible enough to overcome the barriers which have stopped vactrain transportation for the last hundred years. This will require a substantial refocus of our current efforts:

An early Hyperloop decision to permit significant levels of air in the system has complicated the challenge and limited maximum velocity to the speed of sound, which places the project in future competition with existing, famously reliable, high-speed maglev trains. This project's ultimate success will depend almost entirely upon our ability to minimize air levels over thousands of miles of airtight tubing and exit and entry ports so that we can reach the otherwise unattainable velocities proposed by Goddard and Salter—which justify the risk involved in the first place.

The Dubai installation appears to lack adequate defenses against terrorism (which hyperloop's remarkable capabilities will surely invite). One successful terrorist event has the potential to delay, or even cancel public support, and thus the ultimate success of a project which promises to be an environmentally critical element of the world's future transportation network. Given this imperative, deep intrinsic defenses were predominant features in the design of the model I had hoped to create in Maine.

The prerequisite of such a system for arrow-straight trajectories may be easily fulfilled on the flat, relatively empty deserts of Dubai, but in the United States it creates what I believe to be an existential prerequisite for a predominance of deep underground tunneling (which would also contribute to its invulnerability). The saved, otherwise astronomical cost of surface rights of way in the USA, can help improve tunnel technology and fund construction.

The Hyperloop project phasing appears to be inappropriately focused on public perception by offering passenger service before design fundamentals have been rigorously tested or even implemented (as seems to be the case regarding catastrophic failure). After extensive testing on computer models, a complete 1/20th to 1/10th scale model containing all features, especially those involving vacuum generation, airtight and efficient exit and entry and disaster recovery, should be created and then rigorously and repeatedly tested to failure before we can proceed to the next step—which must be cargo delivery, not passenger service. These steps are essential to generate public confidence by demonstrating in advance that the system can be relied upon to support live passenger transportation.

By copying the traditional stop and go scheduled rail system model with its implicit limitations on flexibility and usage volume, Hyperloop, misses the opportunity-of-a-lifetime to create a computer-regulated, continuous-flow dynamic which would integrate seamlessly with most existing land transportation systems—which otherwise have no option but to oppose—and thereby create the likelihood of an exponentially greater market which would in turn help overcome early resistance, and support the likelihood of future economic vitality.

What do I mean by a continuous flow dynamic?

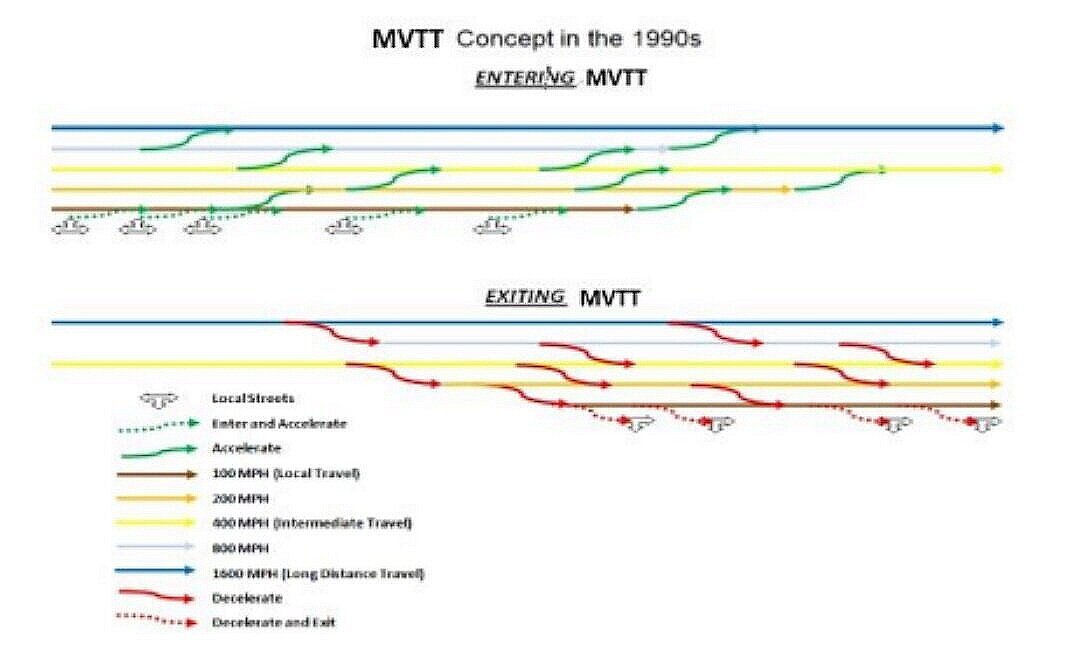

If you decide to travel from New York to LA using MVTT, for example, you would merely jump in your car, and dial your destination to allow computer technology to direct your journey, first through local roads under your own power, then smoothly and seamlessly (without stopping) through various velocity-levels of MVTT until you reach the transcontinental thousands-of-MPH level, which could conceivably carry you to LA in less than an hour, and where you would smoothly descend through various velocity-levels until you reach local streets and your ultimate destination.

Alternatively, you could head to your local bus stop and board a minibus designed to carry you to the nearest MVTT terminal where you would board a passenger bullet programmed to take you to the transcontinental terminal where you would board the bus-bullet destined for LA where you would catch another bus-bullet destined for your more local destination. All passenger bullets would be designed for about 20 passengers which would leave when full, or after a short, optimally-calculated, wait.

What might MVTT mean to America?

In the making and in the running, MVTT would demand the inspired collaboration of large chunks of America’s middle and working classes:

For starters, it would create a massive new industry just to build the thousands of advanced integrated tunnel-borer/creation machines which will be needed (If construction methodology follows that outlined below), first in America, and then worldwide. Millions more of the working middle class would be involved in MVTT construction and operation—and since it would require less than 10% of current energy needs to move freight and get it there in 1/10th the time and at a fraction of the cost, it would give American industry a global advantage and thus generate the indirect need for more workers). Its extreme efficiency and tiny cost per person would generate very healthy profits which would provide the goldrush mentality to overcome resistance, and provide the motivation to form a corporation owned by its tens of millions of participants as well as the level of desirability necessary to attract would-be competitors to the project.

Such, and similar projects, could provide dramatic core elements of a Green New Deal without relying on coercive, and ultimately ineffectual, legislation—and the benefits would extend far beyond conservation and healthy profit margins. Such projects necessarily involve a kind of inspired collaboration that demands civility and integrity for their success, and would collectively tend to restore the relative social harmony, pride in country, vigor and stabilizing norms that characterized our ethos during America’s beginnings.

Combined with similarly dramatic collective achievements possible right now in the spheres of healthcare, education, crime and punishment, etc., etc.—our transportation project would alter the chemistry of our social intercourse, inject hope and optimism once again into America—and inspire us once again to believe in this great country. And such projects are eminently doable. With an investment of 20 Billion (1% of our investment in the war in Iraq), the transportation project alone could begin to drive gains in environmental conservation on a never-before-seen scale.

But of course, as noted above, in today’s America, such projects are unlikely to reach fruition because they will inevitably be opposed by the same status-quo that has been armed to obstruct all such dramatic projects for seventy years—but this time on a never-before-seen scale. Even now, we see the seedlings for this transportation project withering in America as the status-quo more and more pushes the Hyperloop ventures abroad where, once again, the massive implementation and operational benefits won’t accrue to the American working class. Nor will the now existentially-necessary social benefits.

But today, instead of throwing up our hands in frustration at the difficulty of the challenge, or asking government to solve what it cannot solve, it’s time for we the people to hunker down and pull out the stops and give our famous creativity a chance to wrench victory from the jaws of imminent defeat.

ELEMENTS OF DESIGN

As I explored progress concerning mag-lev technology, I saw that conventional thinking about the use of magnetically levitated and propelled transportation kept yielding only marginally better design, and extremely expensive, alternatives to traditional rail. The attempts stayed well within typical rail parameters, and ended not only looking just like traditional rail, but also operating like traditional rail, only a bit quieter and faster. Nobody seemed willing to take the grand leap necessary to reap the most important benefits implicit in the technology.

(Include magnetic River concept in book and MVT)

TO VACUUM OR NOT TO VACUUM

For example, it seemed me that the rewards could only be dramatically improved, and the costs dramatically reduced, if the system were designed to operate in a close to absolute vacuum.

a) Only a vacuum (or close to it) would allow speeds upwards of 2,000 Mph and thus dramatically reduce travel times.

b) Only In a vacuum would the need for propulsion coils (the most expensive element of the system) be dramatically reduced since they would not be as necessary to overcome air resistance but only for initial acceleration, periodic adjustment, and final deceleration and therefore be present only in key locations.

c) Only in a vacuum would the energy expended in magnetic levitation also be drastically reduced because each payload would be in the tube only a fraction of the time needed at lower speeds.

CONTINUOUS FLOW AND INDIVIDUALIZED VEHICLES

Early on I had dismissed the popular idea that mag-lev should be a form of mass transit like the train or the plane. The stop and go and scheduling necessary for these public modes of transport wasted much time and, if the travel velocities and costs were comparable, would always be trumped by the flexibility and continuous flow dynamic of individualized vehicles. The advent of lightning-fast computer technology made continuous flow with individual vehicles eminently possible—and the cost of construction and infrastructure would be comparable, though the propulsion coils necessary to accelerate today’s typical massive train might be reduced in size to support MVTT’s significantly smaller individual payloads. This brings us to the most powerful argument for a continuous flow individualized dynamic—the integration of current transportation dynamics into MVTT would greatly reduce the magnitude of certain opposition to this disruptive technology.

MVTT would therefore be designed to accommodate most current highway transportation vehicles including automobiles and mini-buses. The advantages would be a) construction and operations benefits would be shared by all—not just train-goers, and b) vastly greater popularity within existing industry.

This isn’t to say that MVTT wouldn’t accommodate public, many-passenger bullets where it made sense—just that large multi-car trains would be neither necessary nor desirable since single bullets, each ready to go when full, make more sense in terms of both flexibility and timing.

Of course freight would be a primary user of the system which, depending on the state of advancement in tunnel boring technologies, might be designed to accommodate current freight containers (minus the tractor-trailers). On the other hand, tunnel size is a critical component of our design, and in this case, as discussed below, smaller is better, so before we make such an expensive decision, we should consider what might be better alternatives—such as freight/passenger bullet integration. .

Given the opportunities implicit in MVTT design, current vehicle shapes and characteristic will gradually evolve to more cost-effective configurations. The ultimately evolved passenger vehicle, for example, might be an electric car capable of four hours of local travel outside the system and with physical comfort at least on a par with that of current automobiles, and with additional measures provided to avoid any sense of claustrophobia within the tube. Vehicle windows, for example, might convert to LCD screens to provide a sense of space and/or to provide entertainment while in the tube.

But while the passenger vehicle type and size would vary greatly, the bullets would be standard. This implies the presence o unused space and opens an opportunity that freight, spurred by the omnipresence of sophisticated computerized control, might evolve to a more cellular dynamic which automatically piggybacks suitably sized freight into unused, or specifically allocated, space in passenger bullets (individual and group) according to specific destination.

BENEFITS OF SPEED

I originally figured that the bullets could travel at least 1000 mph with very little energy after initial acceleration. Entrance and exit tubes would serve for acceleration and deceleration and sensors throughout the tubes would keep track of the precise location of all vehicles at all times. Linear electro magnets would be used for acceleration as well as for deceleration where they could regenerate electricity lost—and they would be appropriately scattered throughout the system in order to ensure precise and relative vehicle location of all vehicles simultaneously and to deflect vehicles to other MVTT tubes according to destination.

The tubes wouldn’t need to be big because what was lost in space available could easily be regained with velocity. Triple lanes on current interstate highways, for example, could easily be replaced by a single tube within which 12-foot diameter bullets containing an equivalent volume of passenger and freight could travel at 600 mph with far less vehicle density and arrive in one tenth the time.

By now, however, I suspected that speeds upwards of 3000 mph might eventually be possible, and they would automatically reduce vehicle density in the tube to 2% of equivalent traffic at 60mph—each vehicle arriving in 1/50th of the time. The effect would be that tubes for today’s traffic volume at 1000 mph could accommodate the increasing traffic volume of tomorrow without further modifications other than those needed to increase the speed. This is why we must design trajectories now capable of accommodating at least 3,000 mph travel tomorrow.

This relationship between speed, volume of traffic, and size means that far fewer tubes would be necessary to handle far greater traffic volume than typical expressways, and this too would mean that such a system might be a good deal cheaper to build in the long run than any alternative system. In any scenario, the underpinning software would be programmed to continually balance, safety, density, duration, and velocity for optimal efficiency.

DEPARTURE AND ARRIVAL

I spent a good deal of time thinking about just how incoming traffic could be folded into the high- speed main line, and likewise about how it could arrive at its destination without causing a huge pileup, particularly for high population destinations. I arrived at a kind of layered manifold arrangement which coordinated acceleration and deceleration with start and finish destination requirements respectively.

Acceleration would proceed in stages from up to 60 mph on local streets, through various levels of layered intermediate tubes, doubling in velocity at each stage, and finally to the main tube and maximum velocities. Deceleration would proceed along these same layers but in reverse, finally exiting at 20 mph. At each stage of deceleration, the tubes could double in number to compensate for halved velocities in order to maintain density levels, and in order to provide for numerous possible destination locations. This gradual reduction process, by proliferating vacuum travel at lower speeds as well, might also open the opportunity that future MVTT configurations would offer efficiencies relating to environmental conservation from 50% to closer to 70%.

Thus the same layered manifold concept would serve four purposes: acceleration, deceleration, environmental conservation, and geographic distribution. Single destinations so heavily traveled that they approached saturation on single exit tube service would need additional tubes. Single destinations with very little traffic could eliminate intermediate tubes and go directly to the exit tube where all deceleration would occur.

Exit/Entry points for individual vehicles would be located outside cities where large numbers of vehicles could be launched onto numerous local streets to continue their journeys outside MVTT.

Passenger Bullet traffic coming into a city like Manhattan, however, would enter the city itself and would repeatedly fan out as it decelerated (perhaps in ten-street intervals(, so it could be distributed to hundreds of locations where next generation facilities would be in place. I anticipate dramatic new designs for variable-speed passenger platforms will emerge so that the platform itself travels next to the bullet at the 20mph minimum velocity of the bullet itself, but diminishes incrementally in speed as distance from the bullet increases until It reaches the speed typical of an escalator where entering passengers can step on and head for the bullet, and exiting passengers can step off and walk to their stationary exit point.

The entire system would be continuously monitored and controlled at the highest level by one very fast computer system with simultaneously operating triple backup computers at different physical locations. This highest level would coordinate the processing of potentially thousands of other distributed computers each responsible for the operation of a given segment of the whole and coordinating with individual bullets.

I did a rough calculation of the energy requirements necessary for a typical trip in this almost frictionless system using current retail costs per kilowatt hour and current fuel costs and was startled to see that, depending on overall distance, costs per vehicle would be a tiny fraction of the cost of traveling an equivalent distance by car—somewhere around 1/50—and the longer the trip, the greater the savings. Of course the ancillary benefits would be enormous as well— there would be no pollution (at least locally), and if the system became popular, potentially billions of hours of travel time would be saved for potentially millions of individuals.

I was beginning to appreciate the vast importance of such a system to America and the world’s future—and the vast array of obstacles which would inevitably be presented by enterprise participating in existing transportation dynamics.

THE BULLETS

Utter simplicity would be the most dominant characteristic of the bullets. A speeds upwards of 3,000 mph, there could be no complicated mechanism involved in forward motion that might suddenly become inoperable. We cannot risk even the possibility that unnecessary complexity replicated in millions of vehicles over billions of travel hours will gum up a system traveling at such speeds The ideal would be the external simplicity of a rifle bullet which is nothing more a piece of metal travelling rapidly through space.

These bullets would consist of self-contained cylinders of varying lengths but identical diameter with the identically rounded ends typical of high-pressure containers. These would be constructed of aircraft aluminum or of carbon-fiber whichever made the best sense economically.

Wheels and computer activated shock absorbers would support bullets at slow speeds and all bullets would be capable of self-propulsion if necessary for any reason (power outage, internal maintenance, etc.). This would be driven by an internal electric motor depending optimal design. Above 20mph the bullets would begin to be supported by Halback Arrays (a unique configuration of magnets which focuses the magnetic field).

The means of magnetic levitation is extremely important for MVTT because, at least in my design, the overall cost of both construction and operation of all the magnetic components might actually decrease as the speed increases when using the remarkable power of levitation of the Halback Array.

These powerful magnets would be installed in key locations on the bullets, flush with the outside wall, and they would interact with coils built into the MVTT vacuum tube to provide for magnetic levitation and positioning. As the bullet passes over the coils the Arrays induce a magnetic field capable of levitating the Bullets up to approximately 1.5 inches.

Of course there is a price to pay in drag for the energy necessary to levitate—but whereas that price increases dramatically as velocity increases for airplanes and autos, it does just the opposite for Halback Arrays. At about 15mph, the latest Halbach Arrays have about the same lift-to-drag ration as the best commercial jets traveling at 600 mph. At about 250mph, they are about ten times more efficient meaning that much less power per mile is needed for lift versus that needed for propulsion. At 1000mph they have a better lift-to-drag ratio that the ball-bearings on the wheels of a fast moving conventional train.

This is important for MVTT because in a vacuum, the cost of levitation itself (not propulsion) is the principal non-recoverable cost of each trip.

BUILDING THE TUBES

UNDERGROUND CONSTRUCTION

The first construction option I considered was an arrow–straight route bored using laser guidance to ensure absolute coordination and precision of simultaneous and contiguous boring operations, at intervals of one or two kilometers, and at an average depth of 50 to 100 feet below ground level (to avoid surface property conflicts). The bore would be lined simultaneously as drilled, with the strongest concrete and fiber or steel amalgam available and would house the smaller vacu-tube itself whose components would be manufactured offsite and assembled within the concrete tunnel lining as each one-to-two-kilometer section was completed.

Within the outer tunnel, sufficient space would be provided so that the precise trajectory of the inner vacu-tubes could be continuously monitored with lasers for alignment and, adjusted hydraulically or mechanically to within an eighth of an inch of perfect. To allow for substrate movement on the longitudinal axis, each tube (both layers) would be telescoped slightly into the next. The suspension layer should also include shock absorbers designed to help avoid the effects of earth tremors.

Though automated inspection and repair would be the rule, Human entry should also be designed into the suspension space.

The construction of the vacu-tube itself would be a major expense because switches, coils, and sensors, as well as wires to carry electricity and information, would be integrated into each. Efficient and speedy air locks would be required for entry and exit from the tubes, but bullets would enter through chambers designed to be “skin tight” and allow no space for air to accompany them as they entered and exited the tubes.

Of course, the creation of the vacuum itself is one of the greatest obstacles to success, and at first I planned on vacuum pumps located as appropriate in or above vertical access shafts. As my thinking in general evolved away from hierarchical toward cellular, however, I realized that special bullets could be constructed to operate continuously as “pump pistons” within the vacuum tubes extracting air as they went in order to maintain optimal vacuum conditions—and that transportation bullets themselves could be designed to scoop up any remaining air molecules they encountered.

BORING THE TUNNELS

This tunnel alternative might be considered prohibitively expensive except that technology has largely automated the boring process which has become dramatically more efficient in the last forty years. Furthermore, the anticipated eighteen foot diameter bore size for the concrete liner is only approximately half the cross-section area of the twenty-four foot bore used for most of the world’s “bullet trains” and would reduce the cost of the boring machinery and the energy needed while accelerating the pace of construction.

The boring speed record when I last checked was slightly over an average of 1 Kilometer per month for 10 to 14 foot diameter bores and was held by Robbins Tunnel Boring Machine Inc. The boring velocity of these machines generally increases as the bore size decreases, but at this diameter with optimal substrate conditions, ten of these machines could bore 10 kilometers per month, or 120 kilometers per year; 100 could bore 1200 kilometers per year. Of course bore velocity in difficult substrate would be much slower, and integration of simultaneous tunnel construction would introduce an additional factor, but this at least gives us a general idea of what is involved. Furthermore, with a competitive project of this magnitude, improvements in quality and velocity, and reductions in cost are almost certain.

If MVTT becomes popular, however, it behooves us to create a tunnel-boring-machine-industry in the USA equal to the challenge, and with thousands of state-of-the-art machines created annually to support a global need. The steep rise in power needs implicit in numerous tandem tunnel machines drilling locally might be supported by smaller portable versions of the nuclear powerplants on our submarines.

Besides being optimal for arrow-straight routes, this underground option would also be ideal for access to the modern city. And property acquisition costs should be far less than those necessary for current transportation methods since the vast majority of the distance would be absorbed in underground tunnels with surface property acquisition limited primarily to workspace, vertical access shafts and departure and destination locations.

Current law stipulates that most land owners own the ground beneath them to the center of the earth and have the right to sell access to that land (such as for mineral rights). Since this transportation system is both in the public interest and key to a vital future for our country, the laws of eminent domain could be used to reduce acquisition costs for the right to drill the tunnels with little disruption of surface activity.

Since the tubes would be far smaller than are necessary for typical expressways, they would use only a fraction of the materials necessary per mile, and might actually be less expensive materials-wise than expressways—and labor-wise as well.

Bored Tunnel MVTT Construction Process with vertical wells accessing the route every one to two Kilometers with integrated tunnel creation/boring machines and materials being entered and extracted at the wells as the bore continues. Trajectory coordination precision to within half an inch for hundreds, even thousands, of one or two kilometer-spaced simultaneous boring operations would be obtained through control of the the equipment using Lasers.

ABOVE-GROUND CONSTRUCTION

The second construction concept I considered involved above-ground suspension of only the vacuum tube itself within triangular tower structures at several hundred-foot intervals, the middle being supported by a suspension cable strung between each tower. The tubes would be manufactured from super light-weight materials so that the costs of supporting structures could be minimized. This design, or something similar, might be required in earthquake-prone locations such as along California’s San Andreas Fault.

Of course high-speed tubes installed in this manner would have to be routed carefully to minimize the impact of hilly country but might also combine some boring through the higher hills where the suspension sandwich space between inner and outer tubes could be doubled or tripled to absorb additional shock. Ultimate implementation would probably require a combination of both this method and the tunnels already suggested.

UNDERWATER CONSTRUCTION

The third construction concept involves travel across oceans, seas and waterways. Mimicking some recent through-water highway projects, flotation-positive tubes would be assembled at surface levels in groups that would then be lowered to a depth of about 1000 feet to avoid turbulence and then tethered to the ocean floor. This method would be particularly appropriate to northeast/southwest travel along the east coast of the USA where the tube could be tethered to the relatively shallow continental shelf. The tethers would probably need to be micro adjustable to maintain tube linearity, and fitted with shock absorbers to help compensate for ocean floor tremors. Side-boring technology already exists for oil drilling, and with minor modifications could be adapted for tether anchors. The tubes would probably also require vertical and horizontal framing to eliminate the bending effects of ocean currents.

The great difficulty for this method would be installation over very deep regions. A glance at a map of the ocean floor suggests that there are ways of tethering in the Pacific Ocean by following the shallow waters of the continental shelves north and south along the coasts of North and South America and east and west adjacent to the Aleutian Islands. At 3000 Mph, the detour across the Pacific would have little impact. The Atlantic Ocean has good north-south continental shelf routes but a rather meandering route to and from Europe adjacent to Greenland and Iceland.

Here’s that method in living color:

The cost of MVTT construction in all of these scenarios would of course be expensive, especially during initial years while optimal approaches were being continuously refined, but we must remember that costs exceeding typical highway construction costs might well be offset by reduced right-of-way costs whose elimination would also be a major advantage regarding project duration which, without thousands of legal cases pending, would be a fraction of that of any project requiring widespread surface rights. Of course, the ultimate financial benefits of this project to our society in terms of energy savings and environmental health, as well as our competitiveness world-wide would be vast.

Building and maintaining the vacuum

ESTABLISHING AND MAINTAINING THE VACUUM

The vacuum would be initially established using self-propelled bullets specifically designed to act like pistons inside the tubes working in conjunction with computer coordinated exhaust valves located in access shafts at optimal intervals. When after, several passes, a sufficient vacuum was obtained, thousands of standard passenger bullets would be released into the system to operate at optimal velocity to scoop up remaining molecules until a satisfactory vacuum level was attained to sustain normal operating conditions during which standard passenger and vehicle bullets would continuously scoop up air molecules encountered.

CONTINUOUS FLOW EXIT AND ENTRY

Bus-Bullet passengers would enter MVTT terminals from the street and enter waiting Bus-Bullets with destinations corresponding to their destination, When ready, these would be automatically sealed and accelerated to a velocity of twenty MPH to enter the Vacu-Tube network. This would be accomplished when the now magnetically levitated bullet slid into a skin-tight three stage entry/exit piston, also moving at twenty MPH.. Still moving at twenty MPH, this piston would enter and exit three successively more complete vacuum cylinders at which point it would slow down as it ejected the Bus-Bullet, still moving at twenty MPH, into the entry acceleration tube of the hundred MPH level of the main network where it would remain for local destinations, or move step by step to the velocity level appropriate to its destination, where the entry process would occur in reverse.

Vehicle-Bullets would follow the same procedure, except that their entry would occur at twenty MPH as their vehicle slid from a parallel track into the Vehicle-Bullet which would then enter and exit the three-stage vacuum cylinder and then to the vacu-tube. To exit, the Vehicle-Bullet would execute this same procedure, but in reverse.

DISASTER PREVENTION and RECOVERY

As is the case with any transportation system, our MVTT system would be vulnerable to earthquakes and terrorist attack both from without and within. In our case, the contiguous high speed nature of the system would be particularly attractive to those who would destroy our country.

How can we protect against natural events or outside application of explosives to the tubes? How can we guarantee that someone won’t plant a bomb in a cargo cylinder, or in his or another’s passenger cylinder?

And, finally, how can we protect against cyber terrorism—manipulation of the master software itself?

TUBE INTEGRITY

Built-in security monitoring systems must be present at all entry and exit points (entry ramps, vertical shafts, exit ramps) to ensure protection from terrorists. Laser driven alarms and motions detectors must be installed at all these locations and all motion processed to ensure that it correlates with computer actuated motion of the vehicles themselves. Lasers and motion detectors must also be installed along the entire exposed length of the system (for non-bored systems).

VEHICLE INTEGRITY

Here we have the benefit of decades of experience in airport security and of the latest machinery used to detect dangerous materials, and we should harness as many of these methodologies for MVTT as is feasible—but they won’t be enough. Detection of plastic explosives for example is still not 100% reliable and there are an infinite number of ways to hide and disguise all kinds of potentially damaging material including poison gas.

But because of the highly computerized nature of this system, there are at least four additional ways to ensure that only clean vehicles enter the system.

• The first relies on the uniformity and precision of vehicle construction which would allow the computer to make precise and minute comparisons between images of the vehicles entering MVTT and the blueprint for that vehicle contained in the computer. Any unexplainable anomalies in shape or density would instantly move vehicles to another track for more detailed examination.

• Second, standards of baggage organization might be applied, with specific locations designed into all vehicles for each type of baggage so that anomalies in shape and density would be more easily observable. This need not be onerous for travelers since it would simply amount to a kind of physical structure for the organization of goods—computer here, documents there, clothing there, groceries here, etc., and sloppy organization would merely mean that entry to the MVTT system would take a little longer and/or potentially route one’s vehicle for a physical inspection by trained professionals.

• Third, in order to speed the certification process, the master computer could collect and store detailed images of the baggage typically contained in each specific vehicle entering the system according to its registration number.

• Fourth, sophisticated travel profiles for individual passenger might be automatically developed in order to reduce risk. (Fred Smith weighs 183 pounds and typically travels daily to work with a briefcase and a tennis racket.) Any suspicious variations would move the vehicle to deeper levels of inspection.

Of course most travelers would soon learn that the fastest and simplest way to travel would be lean and well organized, and they would carry specific and recognizable materials with them as a matter of course, and make sure that they weren’t carrying anything suspicious on their bodies or in their vehicles, so with time and improvements growing out of usage, perhaps 90% or better could be 100% computer analyzed and could consistently enter the system without side tracking. Another 5% might enter Stage 2 Security and 3% Stage 3 leaving 2% for the most stringent security checks.

For cargo cylinders we must do all the things that we currently do and in addition some of those listed above for passenger vehicles. We must insist on materials organization so that imaging techniques can be more effective, and we must conduct automatic image comparison for known entities listed in the cargo manifest. In addition we must offer freight cost reduction incentives when customers adhere to carefully designed transparent packing guidelines which minimize opportunities to hide explosive devices or dangerous substances. Those freight cylinders which for any reason are unable to comply will be both more expensive and slower to allow for professional inspection.

COMBATING CYBER-TERRORISM—SOFTWARE INTEGRITY.

Of course, MVTT will employ the best hackers in the world to defend MVTT software against their peers, but there is something else we can do here to protect the system against cyber terrorism.

Each vehicle should carry its own hard-wired chip which constantly confirms that the actual movement of that vehicle conforms precisely to the norms established for safety and the motion that would be activated by the central software itself. Any deviation from these norms anywhere would send a signal to a failsafe system capable of shunting that bullet to another line for inspection or of overriding the main system in order to bring the system to a controlled halt.

IF THE WORST HAPPENS—DISASTER RECOVERY

One of the knottier requirements of any transportation system and one which consumed a disproportionate amount of my attention was the game-plan for catastrophic failure.

The construction of the tube itself and the installation methods discussed above incorporate features intended to minimize catastrophic impact. But how exactly would the system react to an earthquake in California for example, or a terrorist bombing which creates a breach in the tube?

The software must be designed to sense the breach and act. It must do two things instantly:

Hermetically seal off the breach with blast doors in order to limit the impact of a possible explosion and to maintain vacuum conditions in the rest of the system.

Slow the related portions of the system to a stop as fast as possible.

The first objective would be to close the nearest blast doors on both sides of the breach such that the force of any explosion is directed up the vertical access shafts to the surface. The blast doors at the next vertical shafts should also be closed as a failsafe. Blast doors should be present in every vertical access shaft and be designed so that as soon as they begin to close, the force of any explosion drives them shut and exits through the vertical shaft..

FATAL DISTANCE

The second objective is to stop all motion as quickly as possible in order to save as many travelers as possible

Obviously, any passengers physically at the breach or within some “fatal distance” before the breach, is inevitably doomed. This is no different than what occurs within current transportation systems, but in this case because of the instantaneous nature of the controlling system, almost everyone else within the system can be protected from the catastrophe.

Fatal distance is the minimum distance from the breach (or from the blast door) necessary to bring vehicles to a stop without damaging the passengers inside via excessive g-force. The system must both minimize that distance and strive to limit the number of vehicles that can reside within that distance by varying speed and density factors for the vehicles within the tubes.

Though a record peak of 46 g-forces was sustained by John Stapp in 1954, tests show that the average human being can withstand g-forces up to 22 g for up to 10 seconds with no damage if properly positioned relative to the direction of the g-force. Assuming that it is possible to stop our cylindrical vehicles in a controlled manner at this g-force, this means that anyone seated in an appropriately designed seat in a vehicle traveling at 1000 MPH would require a minimum of 2.08 seconds and 1525 feet to come to a standstill and at 4000 MPH would require 8.34 seconds and 24,470 feet.

Therefore, in earthquake-prone areas, if the traffic density is one vehicle per 1525 feet, MVTT velocities could be set at 1000 MPH so that only one vehicle would be inside the fatal distance. If the traffic density is one vehicle per 24,470 feet, 4000 MPH would be possible with the same level of catastrophic vehicle damage. It follows that depending on traffic density, the computer can dynamically calculate what velocity is appropriate particularly when traveling through earthquake-prone geography.

In addition, vehicle speed can be increased and traffic density reduced in these volatile areas by splitting heavily traveled routes into multiple tubes. It is also possible that tests will demonstrate minimal passenger damage at greater g-forces and this would reduce the fatal distance and change the equation. For example if 32g is acceptable for a shorter duration, a vehicle traveling at 1000 MPH would require a minimum of 1.46 seconds and 734 feet to come to a standstill and at 4000 MPH, 5.85 seconds and 17,164 feet. Of course since deceleration at the allowable G force would not occur instantly, these fatal distances must be extended to allow for a safe build to the maximum possible G-force and this of course would add time to the equation.

Also, in extreme cases, a calculation of the g-force necessary to stop a vehicle inside the fatal distance could be made instantly at the moment of the breach, and the system could apply that force in the hope that the passenger could survive it.

But how do we accomplish and control this rate of deceleration?

1. All vehicles must be constructed to withstand at least 60 g-forces and be built so that passengers are always seated optimally to absorb g-forces and on gimbals which respond to these forces by properly positioning passengers.

2. The computer system controlling the networks must act instantly if it senses a breach by filling the Vac-tube with pressurized air for some distance before the blast door and between the blast door and the breach much in the way airbags are inflated in modern cars. This would be accomplished using a smaller pressurized tube running parallel and next to the active tubes and with adjoining computer-actuated variable valves which would open instantly and control the air density entering the breached tube as follows:

a. The density of the air must be greater in the area of the breach (or the blast door) and gradually diminish as the distance from the breach increases. As distance from the breach increases, lesser g-force and longer reaction time is possible and the process can be assisted using the electro-magnets and coils within the tube (optimally including those associated with the Halbach Arrays.

b. The precise distance involved, and the density of the air required, will have been tested during the model construction phase of the project and will be monitored by the computers controlling the reaction to the disaster, and varied as needed to generate the necessary 22-g braking force.

3. Each vehicle will be equipped with its own braking system as well to compensate for its weight relative to other vehicles. That system will control the deceleration via dynamically adjustable air brake foils which control the amount of air flowing around the vehicle as depicted in the figure below. The objective will be to assist the master computer in maintaining the required g-forces for all vehicles adjacent to, or affected by the breach.

Mag-tube Disaster Response Drawing of tube with blast doors activated and air brakes activated

MVTT FEATURES WHICH APPLY TO DISASTER RECOVERY

The overall design and construction of the MVTT system will depend greatly on the nature of the terrain and proximity to quake prone areas as described above, but the minimal requirements will be:

· Telescoping sections

· Double tube construction with shock absorbing sandwich

· Fail-safe duplicate or triplicate electrical systems must operate on both sides of any break

· Self-adjusting micro alignment

· Tube and bullet Integrity sensors every 1000 meters

POST-DISASTER RAPID-REPAIR

It should be noted that by limiting the impact of terrorist bombings to the precise location of impact and to few individuals, one implication—the death of large numbers of innocents—would be greatly diminished. But the terrorist goal of disrupting the overall system must also be addressed if we wish to make MVTT a low-desirability target. There are several factors that would make it difficult to disrupt the system seriously even before a network of MVTT routes large enough to provide viable alternatives for the same destinations is built.

The existing conventional transportation structures will be functional for many years during MVTT‘s evolutionary implementation, and could handle the displaced traffic in passengers and freight.

Since passenger vehicles would be electric and operable outside the tube, they could be detoured around damaged areas while repairs are underway. Tubes could have emergency exits and entrances every ten miles in locations where other entrances and exits are not present.

Over time MVTT will be able to utilize an abundance of alternate Vac-tube routes to move goods and people to final destinations, and these can be instantly activated in the event of an emergency.

Another less obvious deterrent to terrorist action is super-fast repair. A system which can be repaired quickly makes a poor strategic target since the damage is very temporary. This means that the technological approach we take to repair is very significant. Here are some factors which should help:

Pre-manufactured tubes and components for all assembly configurations should be available at all times.

Repairs should be automated and robotic as much as possible since the repair area will in most cases will be hazardous to humans.

Specially designed tunnel borers should be dropped from wells at both ends of the breach and move toward the center while testing and measuring tubes and replacing any that are defective. The actual boring necessary to repair will only occur fairly close to the breach site and most likely be less time-consuming than the original bore.

IMPLEMENTATION STRATEGIES

It is likely that the nation that seizes this opportunity will assume an overwhelming advantage in the movement of goods and people for a long time. The technology will be sought by every other nation on earth and place the originator at a significant competitive advantage in the construction of such systems world-wide.

Of course the political, social and economic barriers to this revolutionary technology will be very high—far higher than those for the electric car, for example, which threatens only a fraction of the interests that would be threatened by MVTT—every existing form of transportation and its suppliers as well as all energy interests in the world, and you and I protecting our jobs, and experts determined to protect the stability of the object of their expertise.

But the advantages are also overwhelming and the existence and funding of recently created Hyperloop companies offer high hopes that the country of the rugged individual is still capable of reversing its own decline.

So it is disappointing, even shocking, to discover that early-on America began to renege on the promise for America in this matter. Dirk Ahlborn, the CEO and founder of HTT spent the end of the summer of 2015 in Asia and released an update to the technology forum IEEE Spectrum in September.

“I can say for sure the first full-length track will be in Asia, the Middle East, India, or Africa,” said Ahlborn. “They have bigger issues and no existing infrastructure, so a real need to build. A system like ours is way more interesting for them than going with high-speed rail.”

Then in June of 2016 Hyperloop Technologies (now Hyperloop One) signed a letter of agreement with Russia to develop mag-lev transportation links in Russia aiming ultimately for a new “Silk Road” capable of whisking containers from China to Europe in a day. Then in August the same company signed a similar agreement with Dubai. In January of 2020,TECH2 reported that India is likely to be the first country to have a working hyperloop.

Of course, these courageous and innovative companies cannot be blamed for looking outside America—enterprise always seeks the best paths with the least resistance in a world where American is probably the path of most resistance.

But this is precisely the wrong outcome for the American middle class and for the future of America itself. And it is exactly what will happen to all other convention-defying ideas with any hope of saving the country from its current downward-spiraling destiny—unless the people, not wealth and politicians, transcend themselves and do something about it.

In the name of those people, America recently spent two thousand billion dollars on a war widely recognized as unnecessary and damaging to global stability. Surely the people can find the will to spend 20 billion, or 1% of the cost of that ill-advised war, to jumpstart a healthy future or America.

Or can they?

Will they allow their binary thinking and their flock psychology and brainstem reactions of fear and greed and anger, to waste their resources in conflict and destroy the future of their progeny?

Or will they find the wisdom and the strength to reach for a healthy future? Will they find a way to loosen convention’s stranglehold on our transportation future—the conviction to deliberately design our MVTT system to help us overcome some of the obstacles.

Here are some ways to maximize the possibility:

OPTIMIZING A MULTIPLICITY OF ADVANTAGES

Design MVTT for the greatest possible audience

Design to Support Existing Vehicles- An MVTT which allows existing vehicles to enter under their own power, travel 2000 miles to a desired destination, and then exit under their own power, would be extremely attractive to most Americans and far more tolerable to existing transportation-related industries because it would cushion the impact and allow time to adapt. Furthermore, the availability of such a capacity would generate a far larger customer base for MVTT. But it would be more expensive to build since it would demand larger tubes than are necessary for an optimally designed passenger carrier. But larger tubes would also allow larger freight containers which might someday be whisked from LA to NY in an hour. There will be an optimal size which would include a capacity to service the vast majority of vehicles and be appropriate for freight, but stay within cost justifiable limits. Maximum vehicle size might be that of a Toyota Coaster passenger minibus.

Continuous Flow Dynamic- A continuous flow freeway dynamic rather than a scheduled stop-and-go rail configuration would add greatly to the appeal of MVTT and also invite more participants. Vehicles, including private and public vehicles would continuously enter and exit with the MVTT computerized operating system guaranteeing integrity, safety margins, and overall harmony. Local small buses for example would drive into waiting “Bullets” and simply dial their destinations, say Boston to LA, and drive out into Hollywood forty-five minutes later. Family cars would do the same, and all Public Passenger Bullets would leave as soon as full and be instantly replaced with the next passenger Bullet.

Maximize Key Competitive Advantages- Realizing that an MVTT with only incremental advantage would diminish enthusiasm and provide naysayers with powerful risk/cost-benefit arguments, we should design from the beginning for a system with built-in potential for speeds of 3,000 MPH or better. The 700 to 1000 MPH currently being discussed will always be optimal for more local transport, but to cross a continent in one hour will always beat four hours. And though it is unlikely that current technologies are sufficiently evolved to support such speeds at the moment, they are theoretically possible, and with our rapidly advancing technology, will soon become attainable. With such a likelihood, it’s important that we don’t design ourselves into a corner, by spending vast resources on routes too curvy to allow the higher speeds, for example, or by designing structures incapable of sustaining a near vacuum. And there is another counterintuitive incentive to design for high speeds—cost. In a near vacuum, the higher the speed, the lower the cost, because almost the same level of energy is required but for a much shorter time, and for a much greater distance. And counterintuitively, a higher speed system also appears to affect construction in ways that can also reduce cost (see below).

Deprive Obstructionists of Issues

A truly high speed system simply can’t tolerate the inevitable curves and ups and downs of almost all existing above-ground routes. But an MVTT at ground level that diverges significantly from such routes will be confronted with literally millions of individual interests and objections— some with real merit, some with none—and thereby furnish numerous and powerful adversaries with millions of delaying tactics which could easily stop the project by decades or even centuries.

As a matter of practicality, and to help counter such resistance we must therefore explore the possibility of increased use of underground tunneling. There would of course be resistance to this methodology as well but it should be far less than that of surface methodology because a tube running an average of 50-100 feet below ground will not encounter the millions of surface structures that give additional weight to obstructionist objections.

Though at first glance a mostly underground transportation system spanning a continent may seem overwhelming, it may in fact be our most realistic option especially given surface right-of way opposition. It also may be the most cost-effective given the cost of overcoming that opposition, and the cost of the support structures that would be necessary for surface routes.

Amazing progress has been made in tunnel boring technology in recent years with bore rates steadily increasing to a current record of nearly one kilometer per month for a fourteen-foot diameter bore. One hundred such machines working in unison could theoretically bore 1200 kilometers per year in similar substrate. Of course, the reality would be far less because the variable nature of substrate.

Nevertheless, even faster bore rates are likely in a project like this as the benefits of scale and competition are added to the mix, and we must also figure that MVTT bore diameters for the structure we are contemplating would be considerably less than that used for conventional roadways (at about half the face-surface area), and that bore rates would be faster for this reason as well.

It should also be noted that vast regions of our nation are so level and uninhabited that underground tunnels may well be built by digging trenches rather than drilling tunnels—possibly next to existing arrow-straight roadways.

A primary emphasis on underground tunnels does not preclude above ground structures which would occur as justifiable and necessary—and suspended above-ground structures would probably be the rule in earthquake-prone areas.

Of course, obstructionists can and do insist that the likelihood of disaster within such a system are unacceptable.

But this will be an evolutionary process which retains the flexibility of existing transportation structures while it gradually builds the network which will provide its own unique flexibility both in terms of construction techniques and operational basics in order to deal with disaster.

Unlike us, MVTT will react to anomalies and emergencies at the speed of light and will be highly controlled and fail-safed as a matter of operational necessity. As a consequence, injury and death rates are likely to be less rather than more than those occurring in current human controlled transportation systems—even with terrorist attacks and earthquakes factored in. In fact, it seems likely that with proper design and procedures, an underground MVTT system would actually be less vulnerable to terrorist attacks than existing systems.

Reducing Cost

I suspect that, in an effort to reduce construction costs relating to levitation for the Hyperloop projects, Elon Musk originally suggested that the tubes retain just enough air to support air skis as a relatively inexpensive means of levitation. But speeds exceeding 700 MPH would be impractical if air skis were to be used because friction, drag, and heat would begin to overwhelm the system. Speeds above 700 MPH would demand the near absence of air in the tubes and the use of magnetic levitation.

One obstacle to this higher speed approach has been that the cost of the necessary levitation windings in tubes for such a configuration would to be prohibitive. But is that true?

In current approaches it appears that the levitation process must be almost contiguous and thus very expensive but it occurred to me that at high velocities, the need for contiguity would be greatly reduced because the magnetic force could be delivered by coils spaced increasingly in direct proportion to the velocity, and that counterintuitively, the higher the velocity, the lower would be both the construction and running costs.

At 2000 MPH such bullets would cover almost 100 feet in only 1/30th of a second and fall vertically during that time only ¼ inch due to the force of gravity. This means that at 2000 MPH levitation pulses to recover that quarter inch could be applied 30 times per second by placing 10 feet of coils (possibly less) for every 100 feet of forward motion, reducing the cost of continuous coil by over 90%. Alternatively the ten feet might be split into one-foot segments every 9 feet. The idea would be to distribute the levitation coils in accord with the velocity of the Bullet. The faster the Bullet, the further from each other would be the coils and the lower the cost.

Of course, such a system would require wheeled Bullets capable of supporting themselves at lesser velocities, but some limited capacity for self-propulsion would be required in any case during power failures and other unanticipated interruptions of service.

Finally, the speed of the overall system will affect the size of the system, since the faster we go, the smaller the overall system needed to transport the same volume of material (freight or people) in the same time frame.

Encourage Participation of Existing Enterprise

During World War II, enterprise all over America converted to support the war effort and did so with gusto. Hollywood excelled at wartime propaganda, Ford made B-24 Bombers and tanks, Bridgeport Connecticut (now so downtrodden and forgotten) made the tools that made the tanks and the engines and the ammunition of war.

Factories that manufactured silk ribbons made parachutes, typewriter factories converted to machine guns parts, undergarment manufactures sewed mosquito netting, and roller coaster manufacturers converted to the production of bomber repair platforms.

This demonstrates that with enough motivation, massive conversion is at least possible. During that war, it was our physical future that was at stake. In this case the issue is the survival of an ideal, an ephemeral concept of liberty which, without our help, may cease to illuminate the future.

Unfortunately, today’s self-centered economy suggests that power is not particularly motivated by the collective good—so we will probably need to harness strong self-interest instead to motivate us to forge a healthy future.

Luckily, given that MVTT shapes collective interest from the naked raw material of self-interest, that should be eminently possible.

Freight First

From a profitability and safety point of view, freight offers the most immediate advantages and incentives, so we must design MVTT to receive and deliver freight as efficiently as possible—and, in order to reduce the opposition of the many existing freight handlers as possible, MVTT Bullets should be designed to accommodate the machinery of existing freight containers manufacturers.

But, because it will be critically necessary to engage the vibrant support of the rest of us, this project must make sure that the features that make human use possible are developed and tested during this initial period—and we must be certain that MVTT incorporates all the failsafe and safety features and capabilities supporting human use outlined in this paper.

Solve Key Problems Before Major Investment.

Start with a computer model and test to breaking point, revise, and test again. Follow with a small, perhaps 20:1 physical model to test all the theories of vacuum retention entry and exit, bullet design, traffic control, catastrophe response, etc. without major investment. When all problems resolved go to full scale testing.

Implement Worst-Case Installations First

Another way to build enthusiasm for MVTT is to begin with a route which is desperately needed—but also easiest to build. The Long Island Expressway, for example, is famous as the world’s longest parking lot, and the island itself is a giant sandbar through which tunnel-boring machines would find little serious resistance.

* * * * * * * * *

By designing MVTT from the beginning to blunt implementation resistance, by minimizing legal opportunities for obstructionism, by maximizing the benefits, and by including existing enterprise in the dynamic, many obstacles can be reduced, but an effective implementation strategy requires the enthusiasm of the society at large. A parallel project called Humanity’s Brain which aims at this objective is under development on the website HumanitysBrain.com. Check it out.

WHAT NEXT?

Why has no one in America actually implemented this obviously superior solution, or even built a comprehensive model so that we can begin to work out the inevitable kinks?

Many “experts” say that the idea is just too expensive.

Poppycock!

The first step must be a computer model and I’m sure there are many creative minds out there that would enjoy the challenge just for the fun of it—an exuberance of technological poetry. I myself am still willing to build a physical model at my own expense.

For the creative mind, there are always solutions, and when one looks closely it becomes apparent that the costs of building and operating MVTT are essentially no worse, and probably far less than those involved with airplane and rail and automobile travel, and are really insufficient to explain the utter absence of activity for so long for this promising technology.

Others say that the consequences of disaster to such a system are unacceptable.

Again I disagree. As discussed above, this will be an evolutionary process which retains the flexibility of existing structures while it gradually builds the network which will provide its own flexibility—and it will be highly controlled and failsafed as a matter of operational necessity, with and death rates which are likely to be a tiny fraction of those occurring in current transportation systems even with terrorist attacks and earthquakes factored in.

The most powerful barriers to this project would include not only the interests of all major types of existing transportation, but also the oil interests as well—and decent people determined to protect the stability of the nation (but blind to the existential nature of our predicament)—and all the rest of us with binary mindsets.

And just the existence of these obstacles will be enough to discourage savvy investors who know that all kinds of invisible and oblique pressures can be, and certainly will be, applied to derail this project—to the everlasting detriment of America.

And of course, those opposing the idea would feel morally as well as economically justified because the idea that such huge change can threaten and even topple our economic system, is real and credible. And the arguments of free market capitalists who, with most of the rest of us, are blind to the damage their profit-making ventures can sometimes do to the long-term stability and health of society in general, would indeed be credible in their short-term context.

But this only reinforces the idea that we need a people-powered—outside government—implementation structure which dictates careful and non-traumatic evolution from the past to the future. It only proves that such a existentially necessary structure can only become possible if we employ a transcendent implementation strategy which incorporates steps which seek to deal directly and indirectly with the barriers to success. In this case that might look something like this:

Create a small Exploratory Consortium

Solicit ideas for a computer model—choose three

Develop models at developer’s expense

Stress-test the models and update accordingly.

Build three corresponding physical models at 1/20 scale and stress test them and update them—still at developer’s cost.

Pick best and incorporate into that model the best features of the others. Repeat test process.

Create an Installation Consortium which includes representatives from all current forms of transportation and energy.

Find a midwestern state willing to collaborate and install full size in fairly short, non-critical route. Stress test with cargo cylinders for one year. Update accordingly.

Stress test for six months with professional drivers. Update accordingly.

Contract with State or Washington to build beneath vicinity of Long Island Expressway or equivalent (50-100 feet below ground) and stress test with cargo.

Test and gradually introduce passenger travel simultaneously increasing speed and usage.

Invite existing enterprise participation in subsequent installations on attractive terms

Annual compensation to all developers according to their degree of contribution will come from 1% of usage charges which will be automatically billed to users at system entry.

This Project, or something like it, isn’t Optional!

If we step back and take a good look, it becomes obvious that the structure described above, or something very similar, is not optional. The nation that seizes this opportunity will assume an overwhelming advantage in the movement of goods and people for a long time. The technology will be sought by every other nation on earth and place the originator at a significant competitive advantage in the construction of such systems world-wide. The very process of construction and operation will galvanize the nation and provide millions, if not tens-of-millions of inspirational jobs.

The excuses we give ourselves when viewed in this light seem petty recipes for inaction. They are handed to us by timid serial thinkers or experts mouthing the rationalizations of vested interests—but also by the justifiable caution of our experts who believe they are protecting the security and continuity of our society. But without a multitude of similarly inspirational and forward-looking projects, the soul of our great nation will simply fade away.

Of course the structure I describe is incomplete, and anything this big is bound to have unintended consequences and unexpected obstacles as well. And it’s true that we can muddle along with our current fuel-gobbling structures while others move beyond us.

But why should we?

This project doesn’t need to start big! For less than 1% of what we spent on a terrible mistake in the Middle East we can work through the growing pains of MVTT and determine if it is indeed as vitally important as it appears. For another 1% of what we wasted in the Middle East, we could have it running below the Long Island Expressway and initiate a new era in energy efficiency and environmental health for the world.

We have been equal to such projects in the past—they are part of our heritage—and those past generations in acting in behalf of their progeny—ourselves—impose an obligation for us to act to support of ours. Courageous people, like Elon Musk, who are motivated at least as much by vision as by profit and who have repeatedly risked their all for their dreams, still exist in this country.

But though they and a few others have already begun to move on this one, the barriers are much higher—far higher than those for the electric car, for example, which threatens only a fraction of the vested interests that are threatened by Vacu-Tube Transportation.

For this reason, in order to succeed at all, they will need the energy of the rest of us. Let’s find the courage in ourselves to support them.

And the Clock is Ticking

The benefits to our country if we build this are incalculable, and the damage we will do if we allow other nations to preempt us on this is likewise incalculable—so if we want renewal instead of decay we need to do this and we must begin today!